There is no such thing as a 117 x 1 grain oblong cut. Grains are units of measure of weight, not lengths. You can not describe a cut as you have, so we have no idea what you really want.

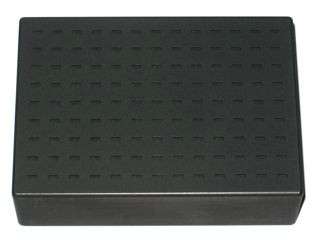

Harold, I think he may have meant that there were 117 oblong depressions, each of which held 1 grain of gold. At least, that's the way I took it.